Our Country Needs More Innovators and Less Fund Managers

It all began about 16 years ago when Mike Yurosek of Newhall, Calif., got tired of seeing 400 tons of carrots a day drop down the cull shoot at his packing plant in Bakersfield. Culls are carrots that are too twisted, knobby, bent or broken to sell. In some loads, as many as 70% of carrots were tossed. And there are only so many discarded carrots you can feed to a pig or a steer, says Yurosek, now 82 and retired. "After that, their fat turns orange," he says.Digging the Baby Carrot, USA Today

Yurosek has always been a "think outside the carrot patch" guy. In the 1960s, Yurosek and Sons was selling carrots in plastic bags with a Bunny-Luv logo, a cartoon that got the farmers in trouble with Warner Bros., which was protective of its Bugs Bunny brand.

Instead of bringing in lawyers and spending a fortune, Yurosek recalls, "I said to my wife — she's a pretty good drawer — 'Hey, draw me up about 50 bunnies, would you? Then we'll send 'em to Warner Bros. and ask them to tell us which ones we can use.' "

The entertainment giant picked one, and Bunny-Luv lived on for the price of a pencil.

The farmer continued growing carrots — and throwing them out — for decades. But in 1986, Yurosek had the idea that would change American munching habits.

California's Central Valley is dotted with farms, fruit and vegetable processors, and freezing plants. Yurosek knew full well that freezers routinely cut up his long, well-shaped carrots into cubes, coins and mini-carrots. "If they can do that, why can't we, and pack 'em fresh?" he wondered.

First he had to cut the culls into something small enough to make use of their straight parts. "The first batch we did, we did in a potato peeler and cut them by hand," Yurosek says. Then he found a frozen-food company that was going out of business and bought an industrial green-bean cutter, which just happened to cut things into 2-inch pieces. Thus was born the standard size for a baby carrot.

Next, Yurosek sent one of his workers to a packing plant and loaded the cut-up carrots into an industrial potato peeler to take off the peel and smooth down the edges. What he ended up with was a little rough but still recognizable as the baby carrot of today.

After a bit of practice and an investment in some bagging machinery, he called one of his best customers, a Vons supermarket in Los Angeles. "I said, 'I'm sending you some carrots to see what you think.' Next day they called and said, 'We only want those.' "

The babies were an economic powerhouse. Stores paid 10 cents a bag for whole carrots and sold them for 17 cents. They paid 50 cents for a 1-pound package of baby carrots and sold them for $1. By 1989, more markets were on board, and the baby-carrot juggernaut had begun.

He died of cancer in 2006. I found this on a blog:

A memorial service is planned for Sunday at 2 p.m. at blah blah blah. Services will be conducted in English, Spanish and Punjabi. (About 5,000 Grimmway Farms employees are Latino and an additional 1,000 are Sikh.)

I admire his family too for including the field workers at his funeral.

2 Comments:

At 1:39 PM, Unknown said…

Unknown said…

I agree with the common sense in this essay by a midwest pig farmer.

Share the wealth by Brent Olson back in 2003-09-03

I have to stop reading the papers. It's just not good for my blood pressure.

Actually, maybe the thing to do is read just one. It's when I start comparing stories that I get tense. Nothing like getting all the facts to confuse the issues. And math -- math is a big mistake. Mr. Melby did me no favors by being such a good math teacher.

Here's the deal. I read an article about how the factories that opened in northern Mexico after NAFTA are now starting to shut down. Companies left Detroit and many other big cities because they said they needed to hire cheap employees in order to remain competitive in a global market. That was about ten years ago; and now those employees in Mexico are getting too expensive. Why, some of them are making over $4,000.00 a year. In the past two years, nearly 500 plants have shut down – many of them moving to China -- because there a worker will assemble computers for $1,182.00 a year.

"So," you might say, "it's a hard old world. I like my cars and appliances cheap. By all means, we need to keep the labor bills low."

That's where having two sources of information becomes such a bother. The same day I saw the factory story I read a different article, on a different topic, but the two linked together. I couldn't believe the figures in the second article, so I looked up the data for myself. In 2002, the average pay of a CEO was $10.8 million. That's not the top five, by the way. That's an average from the top fifteen hundred publicly traded companies. Now, granted, when a few guys make $3-4 hundred million, it does skew the curve a bit. But, still, these boys are doing okay.

I started doing some math. If you multiply 10.8 million by 1,500, you get 16.2 billion (that's with a B) just for head-guy pay. I'm not including all the other members of top management; my calculator doesn't have enough digits to figure that amount of money. Now if these guys could take, oh, let's say, a million dollars a year in salary, which, frankly, many of my friends would consider a fair living wage, we would free up $14.7 billion for other uses. That's a lot of money. That amount would give about 3,500,000 jobs, or if you wanted to bring jobs back to America it would provide $40,000.00 a year jobs for 330,000 Americans. It seems reasonable. Fifteen hundred guys, and a few women, are cut down to a million a year, and in exchange, we put 330,000 people back to work at good wages.

I think a million a year sounds fair. It's not as if these guys are football players, one torn ligament away from the end of their career. Executives can keep working as long as they're capable of knotting their ties. After taxes, even in Minnesota, a million-dollar paycheck would give you about $2,000.00 every day in spendable cash. If you can't live on that, you're too dumb to run a major corporation.

My point here, and I have a couple, is that we've put up with moving so many of our manufacturing jobs overseas because we've been told, repeatedly, that's the price we need to pay to remain competitive. Actually, that's the price we pay so CEOs can line their pockets. That puts a little different spin on it. Keep in mind, some of those $11,000,000.00-a-year guys sat in boardrooms and made the decision to move factories from Detroit to Mexico and blame the unions, then moved the same factories from Mexico to China because those Mexicans were making, at $4,400.00 a year -- too much money.

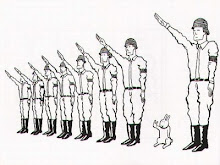

Don't get me wrong -- I'm not some old-line Commie, urging that the wealth of the owners be distributed to the people. I actually like rich people, particularly the ones who start with a good idea, take risks, and become extravagantly wealthy. I'm not talking about them; I'm talking about the hired hands with the nice suits who run the companies built by other people. These are publicly traded companies, meaning the people who buy stocks, probably some of the same people who've been laid off, own them. It'd be interesting if at the next stockholders meeting there were an agenda item like this: "Which would you prefer, that we pay our CEO $11,000,000.00 or use some of that money to keep people working?"

I know how I'd vote.

At 5:55 PM, Wisewebwoman said…

Wisewebwoman said…

Great post, Flimsy.

And if you like Randy Bachman he does a one hour show here on CBC Radio every Saturday night called "Vinyl Tap" which is truly amazing and one of a kind. Sirius 137, I think.

WWW

Post a Comment

<< Home